Dye Penetration Test

Your search for the most reliable dye penetration test service provider in the UK ends here!

Welcome to Gammax Independent Inspection Services Ltd – your go-to specialist in Non-Destructive Testing (NDT) methods since 1995. We serve a large number of clients in a variety of sectors, only offering high-quality services.

A dye penetration test falls under the Liquid Penetrant Inspection (LPI) category among NDT techniques to find imperfections in metal welds.

Liquid penetrant testing, while recognised as having lower sensitivity than magnet particle testing for ferritic objects, is still highly sensitive and straightforward in detecting surface-breaking defects. It also offers the advantage of applying to all nonporous materials.

Furthermore, it has a wide range of surface temperature suitability (10-50 C) and requires meticulous surface cleanliness, ensuring accurate and reliable results. These considerations make it an effective and versatile testing method for flaw detection in various industries.

Our Services

We test welds so that you don’t have to

- GIIS Ltd, Units 12-13, Oaklands Business Park, Bury St Edmunds, Suffolk, IP33 2RW

- 01284 850 888

- info@gammax.co.uk

What is a dye penetration test?

The dye penetration test, also known as liquid penetrant inspection (LPI) or dye penetrant inspection (DPI), is a non-destructive testing method used to detect surface defects or cracks in materials, particularly metals.

It involves applying a liquid dye to the material’s surface, allowing it to seep into any surface cracks or flaws through capillary action. After a specified time, the excess dye is removed, and a developer is applied to draw out the trapped dye.

The dye penetrant test helps reveal defects that may not be visible to the naked eye, enabling further evaluation and necessary repairs.

Why is the dye penetration test important in the metal industry?

The dye penetration test plays a crucial role in the metal industry for quality control and ensuring the integrity of metal components. Identifying surface cracks, fractures, or other defects prevents potential failures, ensuring the structural soundness of metal parts. This test aids in detecting manufacturing flaws, material inconsistencies, or damage caused during the fabrication, welding, or handling processes.

Early detection of defects through the dye penetration test allows for timely repairs or replacements, preventing costly and hazardous consequences, such as equipment failure, structural collapse, or compromised safety. Overall, it helps maintain the high standards of quality and reliability expected in the metal industry.

Benefits of dye penetration test over other NDT methods

- Instant results: The dye penetration test provides immediate visual results, allowing for prompt identification of surface defects or cracks – enabling quick decision-making.

- Cost-effective: Dye penetration testing is relatively inexpensive compared to other non-destructive testing methods. The cost-effective solution for detecting surface flaws also minimises the need for expensive repairs or replacements down the line.

- On-site inspection: The test can be conducted on-site, eliminating the need to transport materials or components to a testing facility. This convenience saves time and ensures an efficient inspection process.

- Water and solvent removable: Dye penetrants used in the test are typically water or solvent-based, making them easy to remove after the inspection. This allows for a clean and residue-free surface, reducing post-testing cleanup efforts.

- V. Dip Tank System: We provide a U.V. dip tank system, which enhances the dye penetration process by utilising ultraviolet light to improve visibility and defect detection. This technology increases the accuracy and reliability of the test results.

Gammax is the best option if you need welding procedures or certifications that adhere to BS EN 15614, BS EN ISO 9606, or ASME IX. We can offer guidance on the diameter and thickness of pipes and plates to be used for maximum qualification.

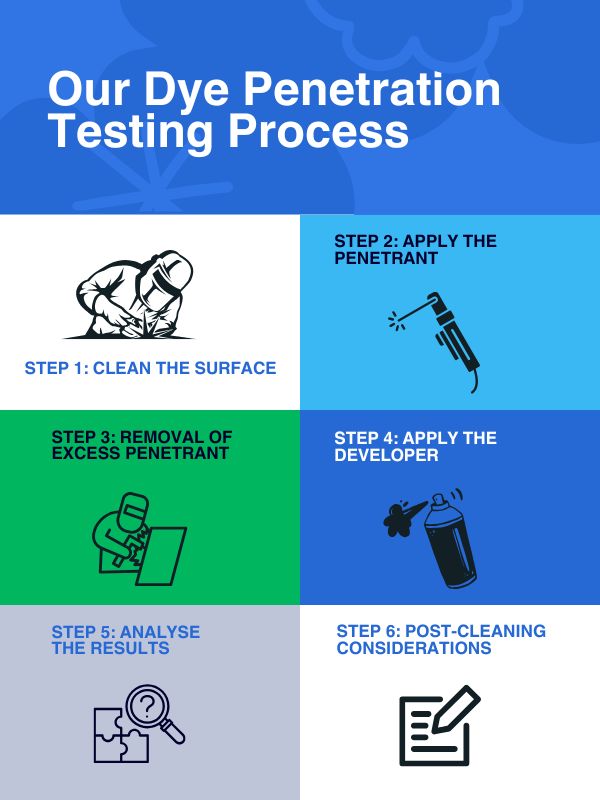

Our Dye Penetration Testing Process

Step 1: Clean the Surface

Our process begins with cleaning the surface to be inspected to get rid of dirt, grease, oil, water, paint or any other contaminants. This cleaning is essential to ensure that the defects are open to the surface and free from any contamination, which allow the dye to freely penetrate.

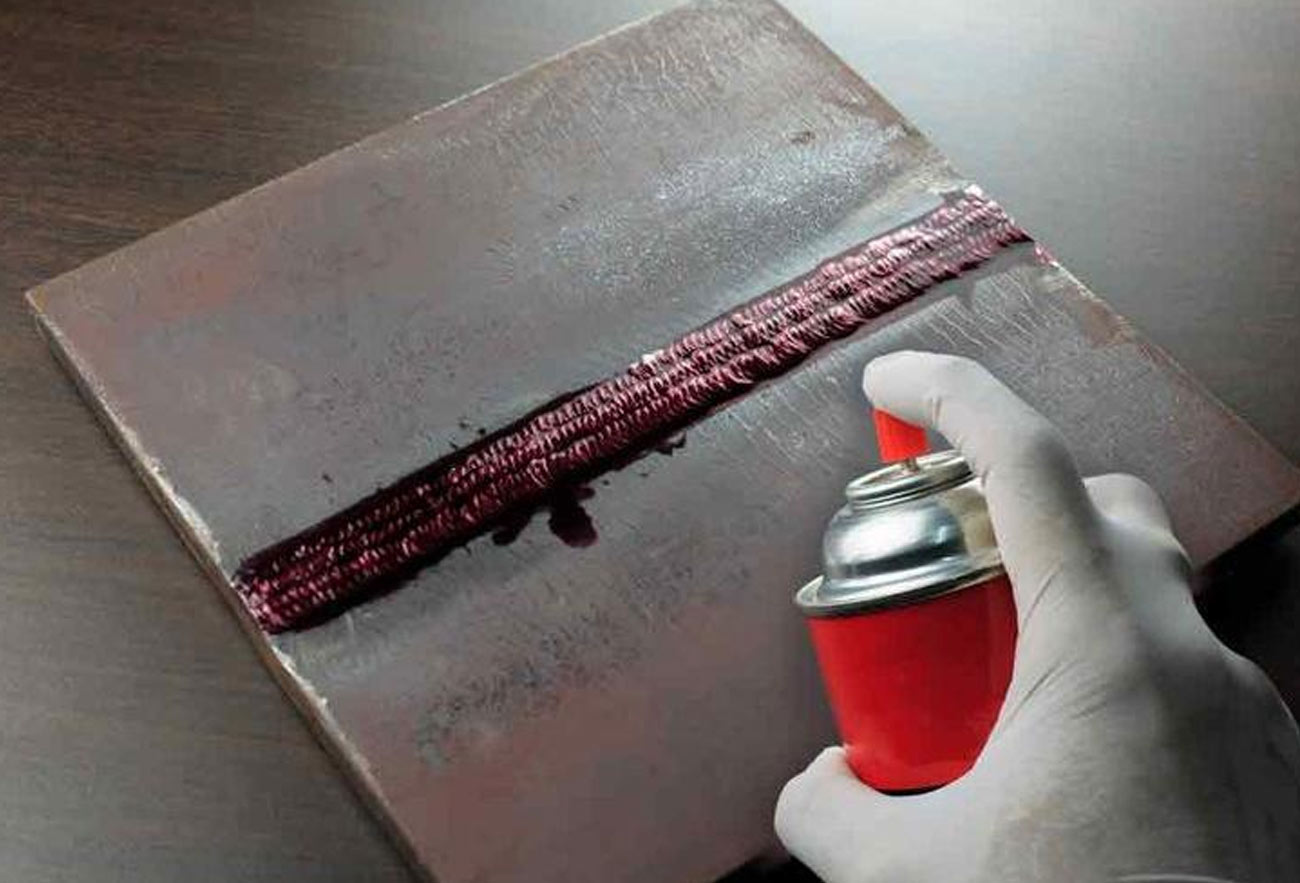

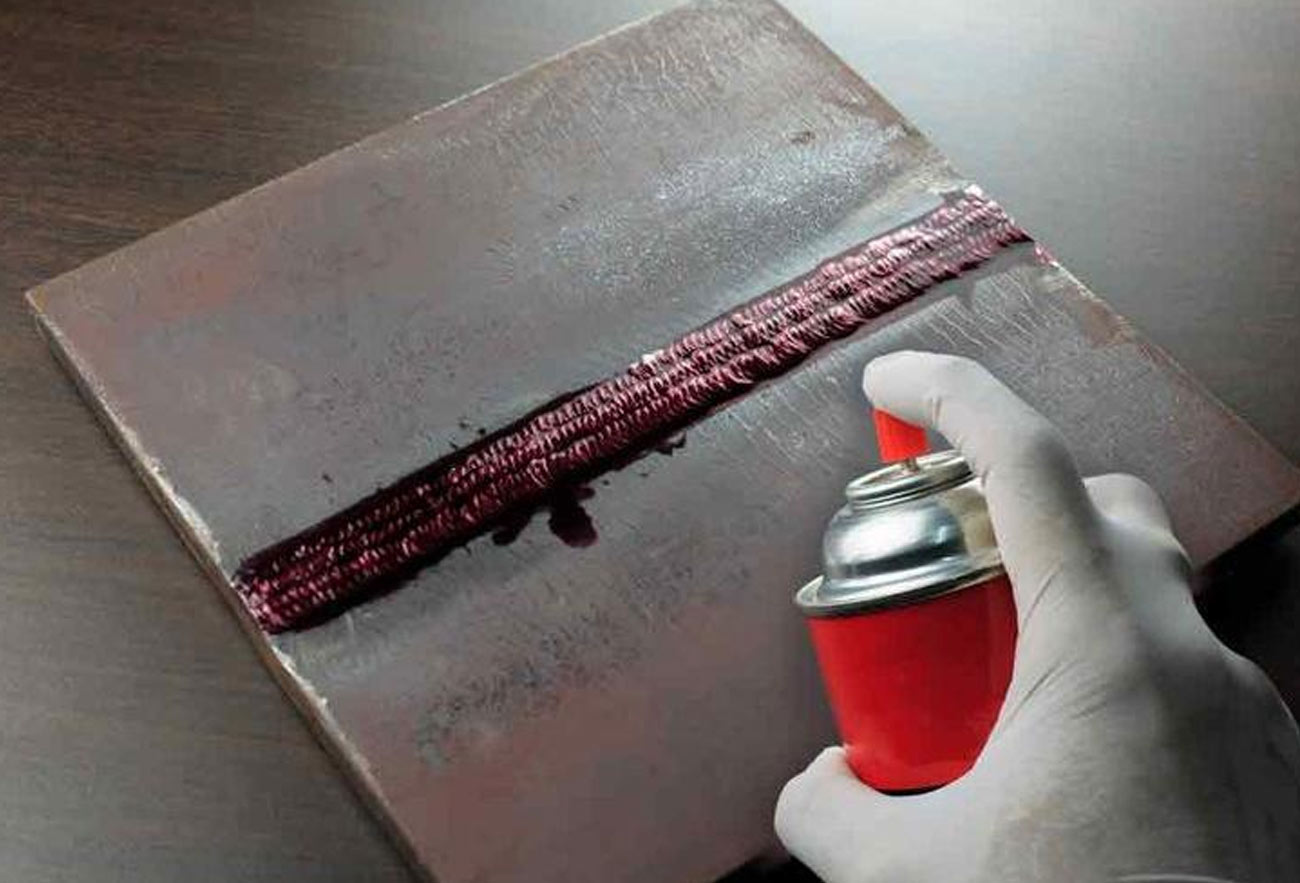

Step 2: Apply the Penetrant

After the surface is clean the liquid penetrant is applied onto the surface and allowed to penetrate into any flaws within the surface face for a specified period of time known as the dwell time. The dwell time can vary from a few minutes to up to an hour depending on the viscosity of the penetrant, the size of defects, and the test material.

Step 3: Removal of Excess Penetrant

When the dwell time is complete, we remove the excess penetrant from the surface, which would otherwise leave a background in the developed area, masking the defects. This could lead to false indications and affect the accuracy of the test. There are several methods for removing the excess dye, such as – water-washable, solvent-removable, lipophilic post-emulsifiable or hydrophilic post-emulsifiable, depending on the type of dye penetrant used.

Step 4: Apply the Developer

After removing the excess dye, we would apply a thin layer of white developer to the surface through dusting, spraying or dipping. The type of developer that would be used will depend on its compatibility with the penetrant. After its application, the developer is kept on the test surface for a sufficient period of time in order to extract the trapped penetrant out from the defects to the surface. This method, known as “bleed out” will indicate the location, orientation and possible types of defects present on the test surface.

Step 5: Analyse the Results

After 10-30 minute of the development time (depending on the penetrant and developer used), we would use adequate light to examine the defects. The development time allows blotting action to occur which will make the cracks and other defects visible. The examination will be carried out using regular light for visible dye penetrant and ultraviolet (UV-A) radiation for fluorescent penetrant.

Step 6: Post-Cleaning considerations

The last step involves cleaning the material thoroughly post inspection. This is where the developer and the penetrant are removed to leave the surface in its original form.

Application

Dye Penetration Test is used to detect defects in the following materials:

● Brass

● Cast iron

● Aluminium

● Copper

● Stainless steel

● Ceramics

● Certain plastics

Due to its flexibility of use Dye Penetration Test is used across various industries for testing magnetic and non-magnetic, metallic and non-metallic, as well as conductive and non-conductive materials.

Why Choose Gammax for Dye Penetration Test?

Adherence to Industry Standard

We are your best option if you need welding procedures or certifications that adhere to BS EN 15614, BS EN ISO 9606, or ASME IX. This ensures that our tests are done according to the highest standards and the results you receive will be recognised all across the UK and beyond.

Transparent Communication

We believe in transparent communication. Our team provides you comprehensive reports detailing the inspection process, findings, and expert recommendations. You can also contact us for a follow-up consultation and discuss any concerns you may have or for corrective actions.

Latest Equipment

We use only the latest equipment to carry out Dye Penetration Test or any other non-destructive testing. Our methods are highly sensitive and can detect even the smallest of surface discontinuities in a variety of materials including metals, alloys, glass, ceramic as well as plastic.

Customised Solutions

We work closely with you to understand your specific needs. This allow us to tailor our inspection process as per the material used, the expected service conditions of the part, and the nature of the potential defects. This customised approach ensures a thorough inspection that fully aligns with your specific situation.

Need some advice? Or want to book in?

Unlock precision and peace of mind. Call now for expert Dye Penetration Test services.

Gammax Services

Gammax Independent Inspection Services Ltd is the leading Non Destructive

Testing Specialist

Services

Radiography

Radiography utilises penetrating radiation generated electrically by x-ray equipment or by the nuclear decay process seen in radioactive isotopes such as Iridium 192.

Weld Procedures

We can advise you on selection of pipe/plate diameters and thicknesses in order for you to obtain the maximum qualification range.

Liquid Penetrant Inspection

Although accepted as being the less sensitive method when compared to magnet particle testing for ferritic objects liquid penetrant inspection

Alloy Verification - PMI

In the process of Alloy Verification the Niton XLt 898 is the ideal tool for performing Alloy Verification/PMI.

Ultrasonic Testing

Ultrasonic testing involves the sound travelling as a wave form through any given material with a constant velocity..

Magnetic Particle Inspection (MPI)

Magnetic Particle Inspection is used on Ferromagnetic materials in order to detect surface breaking flaws and occasionally sub-surface flaws.

FAQ

Most frequent questions and answers

It is common practice to use dye penetrant inspection (DPI) to find cracks in a surface. This non-destructive testing method, which is also called liquid penetrant inspection (LPI), is a cheap way to find surface-breaking flaws like cracks, pores, laps, seams, and other breaks in the surface.

DPT is based on the principle of CAPILLARY ACTION. Because of this, liquid tends to flow or seep into any small opening, even when outside forces like gravity try to stop it. This phenomenon occurs due to molecular attraction.

The chemicals used in dye penetrant tests typically include a penetrating liquid (dye), a developer, and a cleaner or solvent.

The dye penetrant process involves applying a penetrating liquid (dye) to the surface of the material being tested, allowing it to seep into any surface defects. After a specific dwell time, the excess dye is removed, and a developer is applied to draw out and make the defects visible.

The advantage of dye penetrant testing is its ability to detect surface defects, cracks, and discontinuities in various materials quickly. It is a cost-effective method that provides visible indications of flaws, allowing for timely repairs or further inspection if necessary.